Perimeter protection: how to choose a video surveillance system for industrial facilities

Video surveillance systems have become an integral part of comprehensive security for industrial sites. They are used not only for perimeter security but also for ensuring employee safety, monitoring production processes, and even optimizing business operations. In this article, we will discuss how to choose a video surveillance system for industrial perimeter protection – and what additional tasks it can address.

What is an industrial facility?

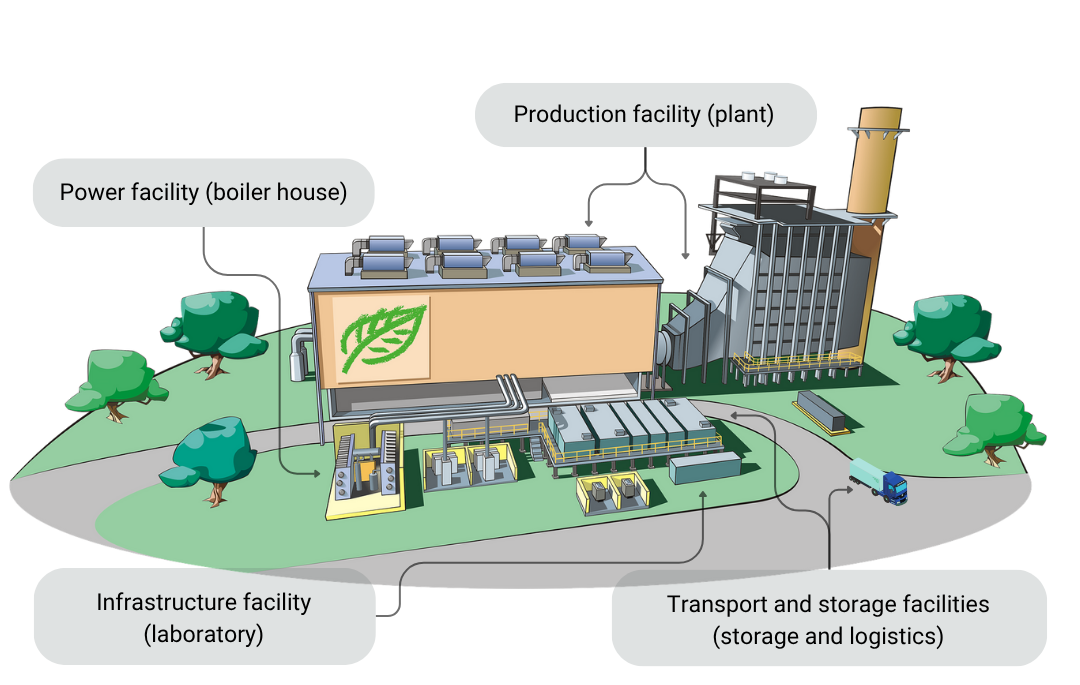

As we can conclude from the Wikipedia’s definition of industry, it’s a group of enterprises engaged in the extraction of raw materials and fuels, production of energy and tools, processing of materials and products, and manufacturing of consumer goods. Simply put, industrial facilities are complexes of buildings and structures united by a common technological purpose: the production of goods or provision of related services.

Typically, such enterprises include production lines, technical installations, utility buildings, and utility networks. All of them require reliable security.

Industrial facilities can be broadly categorized into four main types:

Why is video surveillance necessary at industrial facilities?

One of the main features of industrial facilities is the heightened security and reliability requirements for such complex enterprises. It is caused by their scale, technological complexity, and high production risks. Given this, the main objective of security systems at industrial facilities is to ensure the safety of both the facilities and workers, as well as to prevent emergency situations. Video surveillance can assist with all these tasks, particularly with perimeter security.

In the next section, we will look at the key parameters to consider when choosing video surveillance for perimeter protection.

Factors to consider when choosing a video surveillance system for industrial facilities

When selecting a video surveillance system to secure the perimeter of an industrial facility, it’s essential to consider not only technical characteristics but also a range of organizational and strategic factors. Below are the key ones.

1. Economic factor

Investments in security for industrial facilities pay off manyfold over time by reducing risks, losses, and incidents. However, budget constraints are often a pressing issue: not every facility can afford to implement a full-scale video surveillance system all at once. Deploying video surveillance undoubtedly requires financial investment, so it’s important to choose solutions that either align with the required pricing from the outset or allow for a gradual transition – enabling step-by-step scaling, adding cameras and features without completely replacing the equipment.

2. Security effectiveness

In video security, what matters is not just the number of features but also the quality of the core function – protecting the perimeter of an industrial facility. It’s crucial to select solutions whose performance leaves no room for doubt.

Reliability can be assessed in two ways:

Since industrial security is a sensitive field, access to deployment data may be limited. Thus, the ability to test a solution before purchase becomes a significant advantage.

3. Solution capabilities

Ask yourself: why do you need video surveillance at your industrial facility? Common objectives include intrusion prevention, stricter or automated access control, and employee time tracking. Beyond that, modern solutions offer advanced video analytics and even AI-powered technologies that can detect not only unauthorized entry but also other critical events – such as fire outbreaks, conveyor line stoppages, or production defects. Professional solutions can also be customized to project-specific needs. For example, a surveillance system can be trained to intelligently analyze on-screen activity and detect events unique to a particular industrial facility – such as abnormal employee behavior in gas leak-prone areas or cracks forming on a deepwater drilling rig.

Even small details like notification systems matter. Industrial facilities are typically large complexes, and frequent false alarms don’t just waste the responsible personnel’s time – they can pose a security risk. An overload of irrelevant alerts or poorly designed notifications increases the chance of missing a critical event. That’s why it’s vital to choose a reliable solution that delivers only relevant alerts through a user-friendly communication channel.

4. Scalability

Rarely does an industrial enterprise deploy a surveillance system across its entire premises all at once. Implementation usually happens in phases, sector by sector. Additionally, potential future expansion of production areas must be considered.

Opt for solutions that allow:

5. Ease of staff training

Another factor is how quickly personnel adapt to learning new systems. A video surveillance system at an industrial facility should be intuitive to operate, requiring minimal training effort, and resistant accidental errors. Ideally, it should avoid unnecessary complexity.

6. Adaptability

The operating conditions for video surveillance at industrial facilities differ significantly from those in offices or kindergartens. Depending on the industrial facility type, cameras may be exposed to aggressive environmental factors, chemicals, extreme temperatures, communication interference, and more. Therefore, special attention should be paid to whether the solution can function in such extreme conditions. In particularly challenging cases, only a select range of equipment can operate, making flexible surveillance systems that work with any cameras and hardware – without limiting your choices – the only viable option. This allows you to select specialized equipment (such as heat-resistant or corrosion-proof cameras) without worrying about compatibility with your surveillance software.

7. Integration with existing infrastructure

Video surveillance often needs to become a part of a broader security system, meaning it should offer integration capabilities with existing access control systems, alarm methods, SCADA systems, Industrial IoT (IIoT) sensors, and sometimes even with hybrid video surveillance systems already in place. It’s recommended to choose solutions that support various integration methods.

8. Data storage

The larger the project, the greater the area that needs camera coverage. More cameras mean more footage to store. Consequently, you should choose surveillance solutions that don’t impose storage limitations. This is a common issue with ready-made NVR (network video recorder) solutions that come “as-is” with limited storage capacity. In this regard, a combination of surveillance software and a computer might be preferable – this setup allows for better control over disk space and other hardware components.

We should also mention server redundancy here – it’s better to choose a system that features hot or cold redundancy mechanisms, meaning backup servers can automatically take over if the primary server fails. This helps ensure uninterrupted operation.

9. Cybersecurity.

Cybersecurity requirements are now ubiquitous and apply to industrial facilities as well. While protection against data leaks and unauthorized access should be implemented systematically – primarily at the level of network infrastructure and strict corporate access policies – it would still be beneficial if your chosen video surveillance system uses proprietary protocols and secure connections.

How to choose a video surveillance system for protecting industrial facility perimeter

Having examined the challenges faced by video surveillance at industrial facilities and the key aspects to consider when selecting an appropriate solution, we can now answer the questions “How to choose a video surveillance system for protecting industrial facility perimeters?”

To select the right system, follow this step-by-step approach:

1) Define the tasks your industrial facility’s video surveillance needs to perform (currently, in the near future, and with a 10-year perspective), then shortlist security products capable of executing these tasks.

2) Assess operating conditions: if challenging environments or special requirements exist, eliminate solutions that don’t support operation in such conditions.

3) Determine your budget: select solutions that fit your price range.

4) Evaluate functionality: choose solutions that not only handle core tasks but also support additional practical applications (e.g., not just perimeter protection but also recognizing whether employees are wearing personal protecting equipment), or those that allow customization for project-specific needs.

5) Consider integration requirements if the solution needs to work with existing systems. Keep only options that support this.

6) Select products that meet your preferences for data storage and redundancy.

7) Test the solution before purchasing whenever possible to verify its performance quality, fault tolerance, and how feasible it will be to train your personnel to use it.

It might seem that such strict selection criteria would leave no viable solutions, but fortunately, the market offers numerous video surveillance products, making it possible to find an ideal solution for any conditions.

For example, the Xeoma video surveillance software easily meets all the above requirements for most industrial facilities – not just for perimeter security, but also for practical applications such as employee monitoring, defect detection on conveyor belts, automated parking solutions, and anti-terrorism measures. See below for more details on these features.

What additional tasks can video surveillance perform at industrial facilities?

Recently, there has been a steady trend toward digitalization and improving efficiency across various industrial processes. Therefore, when choosing a surveillance system for industrial facilities, it’s also worth considering the potential for video analytics – either now or in the future.

Here are several application tasks video surveillance can perform at an industrial facility:

Production monitoring: Any production downtime translates to financial losses for a company. The “Detect only absence of movement” feature in the smart “Motion Detector” helps minimize such losses by timely identifying pauses in production line operations. This proves particularly valuable in automated environments with minimal human presence – here video surveillance helps quickly pinpoint the exact section of the production line where a malfunction occurred.

Fire safety: The “Smoke detector” will help protect the factory from fire-hazardous situations. The module is able to locate the source of the fire, instantly inform the security service and call the fire department.

Monitoring the activities of employees: If your factory assumes constant movement during the shift, then the “Loitering Detector” will help detect those who have been idle for too long during working hours. At the same time, the “Face Recognition” module will help you immediately identify who these employees are.

Monitoring compliance with safety regulations: At enterprises with an increased risk of injury, compliance with safety regulations is critically important. The “Detector of Construction Site Safety» detects workers who do not wear protective work clothes.

Accounting of working hours and detection of unauthorized persons in the enterprise: Thanks to the “Face Recognition” module, you will immediately know if there is an intruder on the territory. In addition, the “FaceID” module, which works in pair with the “QR Code Recognition” or the “Smart Card Reader”, allows only employees to enter the enterprise. The same modules will help you calculate the time spent by employees on shift.

Control of the goods in the warehouse: The correct storage of goods in warehouses implies compliance with a certain temperature regime and humidity indicators. The «Text Recognition» module is able to read the indicators of the sensors used and send signals if the storage mode is disrupted.

Crime prevention in production: For facilities containing expensive equipment that is always located in the same place, the “Detector of Abandoned Objects” helps prevent or quickly detect theft attempts. The “Face detector (emotions)” identifies employees displaying poor morale who might exhibit behavior potentially hazardous to production or other workers.

Enhancing other systems’ efficiency: Xeoma integrates with external devices and systems: “Camera-Embedded Detector” (using camera’s built-in detectors); the “GPIO module” (working with ARM device pins); “Modbus” controllers (e.g., in smart home systems); camera support, etc. This enables maximally effective, comprehensive, and continuous production monitoring.

And that’s not all. The Xeoma video surveillance software offers over 100 features, including 30+ video analytics tools, as well as the ability to develop custom detectors tailored to your needs. Whatever the task, you can trust Xeoma to handle it.

Conclusion

Perimeter protection at industrial facilities is not just a security concern – it’s a critical factor for ensuring stable, uninterrupted operations. Modern video surveillance systems can do much more than prevent intrusions and control access; they’re capable of performing numerous practical tasks – from monitoring production processes to analyzing employee performance efficiency.

Selecting the right solution requires a comprehensive approach that considers the facility’s specific characteristics, operating conditions, integration requirements, and budget constraints. A properly chosen video surveillance system isn’t an expense, but rather an investment in your enterprise’s reliability, security, and operational efficiency.

If you’re looking for a solution that performs effectively in industrial environments, provides intelligent perimeter monitoring and seamlessly integrates with your IT infrastructure – consider Xeoma software. This proven solution has already established itself in the industrial sector, helping facilities worldwide maintain reliable security and control over their critical infrastructure.

August 21, 2025

Read also:

Video surveillance installation at the industrial enterprise

Warehouse video surveillance

Video surveillance for business and major systems

Streamlining your business with video surveillance